Water treatment

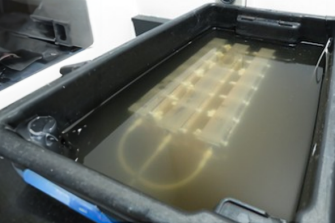

The centre has been at the forefront of membrane research for water and wastewater treatment activities in Australia for over 25 years, and continues to do so through engaging with organizations such as the NCEDA and AWRCoE, and many of our industrial partners from Australia such as Sydney Water, Water Corporation, City West Water, Veolia Water Australia, as well as international partners such as Beijing Origin Water. The centre views new membrane material development as a key research area over the next few years and vital for the next step change improvement in membrane performance.

For further information

Please contact Prof. Greg Leslie | UNSW

Ph: +61 2 9385 6092

E: g.leslie@unsw.edu.au