- UNSW

- ...

- UNESCO Centre for Membrane Science and Technology

- Our research

- Archived research projects

- Separation performance of dip-coated microporous hollow fibre polymer inclusion membranes (PIM)

- Home

- About us

-

Our research

- Membrane material development

-

Water treatment

- Study of floc strength and stability during direct filtration of surface water

- Mass and heat transfer in submerged vacuum membrane distillation and crystallization

- Development of novel membrane integrity tests for virus sized particles

- Reuse of old reverse osmosis membranes used in desalination plants | UNESCO Centre for Membrane Science and Technology - UNSW Sydney

- Optimisation of hybrid coagulation/submerged membrane bioreactor treatment of wastewaters | UNESCO Centre for Membrane Science and Technology - UNSW Sydney

- Developing national validation guidelines for MBRs in water recycling

- Assisted forward osmosis for energy savings in RO desalination

- Characterising nanostructure functionality of conventional and advanced polymeric membranes using electrical impedance spectroscopy

- Optimising low-pressure membrane pre-treatment for desalination | UNESCO Centre for Membrane Science and Technology - UNSW Sydney

-

Process design & modelling

- Computational fluid dynamics modelling of Membrane Bioreactors

- Resilience modelling of advanced water treatment plants

- Mechanical reliability of microporous membranes in water recycling applications

- Optimisation of Membrane Distillation Processes

- Feedback Destabilizing Control of Electro-osmotic Flow

- Greenhouse gas technology

- Bio-separations

-

Food & agriculture

- Membrane facilitated subsurface drip irrigation

- Milk ultrafiltration

- Protein recovery from potato processing water using ultrafiltration membrane

- Phosphorus recovery from wastewater

- Sequential chemical and enzymatic cleaning of ultrafiltration membranes in dairy applications

- Application of membrane separation process in concentration and separation of polyphenol compounds for evaluation of their health benefits

- Optimising low-pressure membrane pre-treatment for desalination

-

Archived research projects

- Composite biocatalytic nanoflower

- Superhydrophobic Membranes for Membrane Distillation Applications

- Polymers for Isoporous and Functional Membranes

- Separation performance of dip-coated microporous hollow fibre polymer inclusion membranes (PIM)

- Improvement in Fouling Release Properties of Ultrafiltation PVDF Membranes

- Thin Film Nano-composite Membrane Fabrication for Carbon Dioxide Capture from Flue Gas

- MOF based highly efficient gas separation membrane

- Biocatalytic membrane reactors for greenhouse gas capture

- Evaluation of CO2 Capture with High Performance Hollow Fiber Membranes from Flue Gas: A Pilot Scale Study

- Improved Carbon Dioxide Separation Performance with Additives of PEO/PDMS Copolymer in PPO Membranes

- Our facilities

- Our services

- Contact us

- Home

- About us

-

Our research

Water treatment

- Study of floc strength and stability during direct filtration of surface water

- Mass and heat transfer in submerged vacuum membrane distillation and crystallization

- Development of novel membrane integrity tests for virus sized particles

- Reuse of old reverse osmosis membranes used in desalination plants | UNESCO Centre for Membrane Science and Technology - UNSW Sydney

- Optimisation of hybrid coagulation/submerged membrane bioreactor treatment of wastewaters | UNESCO Centre for Membrane Science and Technology - UNSW Sydney

- Developing national validation guidelines for MBRs in water recycling

- Assisted forward osmosis for energy savings in RO desalination

- Characterising nanostructure functionality of conventional and advanced polymeric membranes using electrical impedance spectroscopy

- Optimising low-pressure membrane pre-treatment for desalination | UNESCO Centre for Membrane Science and Technology - UNSW Sydney

Process design & modelling

- Computational fluid dynamics modelling of Membrane Bioreactors

- Resilience modelling of advanced water treatment plants

- Mechanical reliability of microporous membranes in water recycling applications

- Optimisation of Membrane Distillation Processes

- Feedback Destabilizing Control of Electro-osmotic Flow

Food & agriculture

- Membrane facilitated subsurface drip irrigation

- Milk ultrafiltration

- Protein recovery from potato processing water using ultrafiltration membrane

- Phosphorus recovery from wastewater

- Sequential chemical and enzymatic cleaning of ultrafiltration membranes in dairy applications

- Application of membrane separation process in concentration and separation of polyphenol compounds for evaluation of their health benefits

- Optimising low-pressure membrane pre-treatment for desalination

Archived research projects

- Composite biocatalytic nanoflower

- Superhydrophobic Membranes for Membrane Distillation Applications

- Polymers for Isoporous and Functional Membranes

- Separation performance of dip-coated microporous hollow fibre polymer inclusion membranes (PIM)

- Improvement in Fouling Release Properties of Ultrafiltation PVDF Membranes

- Thin Film Nano-composite Membrane Fabrication for Carbon Dioxide Capture from Flue Gas

- MOF based highly efficient gas separation membrane

- Biocatalytic membrane reactors for greenhouse gas capture

- Evaluation of CO2 Capture with High Performance Hollow Fiber Membranes from Flue Gas: A Pilot Scale Study

- Improved Carbon Dioxide Separation Performance with Additives of PEO/PDMS Copolymer in PPO Membranes

- Our facilities

- Our services

- Contact us

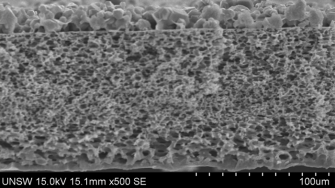

Polymer inclusion membranes (PIM), when compared to supported liquid membrane (SLM) exhibit excellent stability while retaining most of the advantages of SLMs. The current study on PIM focuses on flat-sheet membranes, however, by contrast hollow-fiber membranes possesses other advantages, such as high packing density, high surface area and low transport resistance. In this project, a preparation method using dip-coating technique for PIM was developed and evaluated. The coated membrane fibe...

Polymer inclusion membranes (PIM), when compared to supported liquid membrane (SLM) exhibit excellent stability while retaining most of the advantages of SLMs. The current study on PIM focuses on flat-sheet membranes, however, by contrast hollow-fiber membranes possesses other advantages, such as high packing density, high surface area and low transport resistance. In this project, a preparation method using dip-coating technique for PIM was developed and evaluated. The coated membrane fibers were evaluated for their microscopic structure by SEM and separation performance through mass transport experiments of cadmium.

Factors influencing the mass transport in the extraction tests including the thickness of coated PIM on hollow fibers, feed flow rate, carrier concentration and choice of substrate were studied. The preliminary results indicated that coated PIM layer thickness and substrate type are crucial factors affecting the transport rate. Composite hollow fiber PIM membrane will be compared with the flat-sheet membranes and further optimization will be made.

- Research team

- Collaborators

Xiong Yi Farzad

Rahim Rajabzadeh

Hongyu Li

Vicki Chen

Spas Kolev

University of Melbourne