- UNSW

- ...

- UNESCO Centre for Membrane Science and Technology

- Our research

- Food & agriculture

- Milk ultrafiltration

- Home

- About us

-

Our research

- Membrane material development

-

Water treatment

- Study of floc strength and stability during direct filtration of surface water

- Mass and heat transfer in submerged vacuum membrane distillation and crystallization

- Development of novel membrane integrity tests for virus sized particles

- Reuse of old reverse osmosis membranes used in desalination plants | UNESCO Centre for Membrane Science and Technology - UNSW Sydney

- Optimisation of hybrid coagulation/submerged membrane bioreactor treatment of wastewaters | UNESCO Centre for Membrane Science and Technology - UNSW Sydney

- Developing national validation guidelines for MBRs in water recycling

- Assisted forward osmosis for energy savings in RO desalination

- Characterising nanostructure functionality of conventional and advanced polymeric membranes using electrical impedance spectroscopy

- Optimising low-pressure membrane pre-treatment for desalination | UNESCO Centre for Membrane Science and Technology - UNSW Sydney

-

Process design & modelling

- Computational fluid dynamics modelling of Membrane Bioreactors

- Resilience modelling of advanced water treatment plants

- Mechanical reliability of microporous membranes in water recycling applications

- Optimisation of Membrane Distillation Processes

- Feedback Destabilizing Control of Electro-osmotic Flow

- Greenhouse gas technology

- Bio-separations

-

Food & agriculture

- Membrane facilitated subsurface drip irrigation

- Milk ultrafiltration

- Protein recovery from potato processing water using ultrafiltration membrane

- Phosphorus recovery from wastewater

- Sequential chemical and enzymatic cleaning of ultrafiltration membranes in dairy applications

- Application of membrane separation process in concentration and separation of polyphenol compounds for evaluation of their health benefits

- Optimising low-pressure membrane pre-treatment for desalination

-

Archived research projects

- Composite biocatalytic nanoflower

- Superhydrophobic Membranes for Membrane Distillation Applications

- Polymers for Isoporous and Functional Membranes

- Separation performance of dip-coated microporous hollow fibre polymer inclusion membranes (PIM)

- Improvement in Fouling Release Properties of Ultrafiltation PVDF Membranes

- Thin Film Nano-composite Membrane Fabrication for Carbon Dioxide Capture from Flue Gas

- MOF based highly efficient gas separation membrane

- Biocatalytic membrane reactors for greenhouse gas capture

- Evaluation of CO2 Capture with High Performance Hollow Fiber Membranes from Flue Gas: A Pilot Scale Study

- Improved Carbon Dioxide Separation Performance with Additives of PEO/PDMS Copolymer in PPO Membranes

- Our facilities

- Our services

- Contact us

- Home

- About us

-

Our research

Water treatment

- Study of floc strength and stability during direct filtration of surface water

- Mass and heat transfer in submerged vacuum membrane distillation and crystallization

- Development of novel membrane integrity tests for virus sized particles

- Reuse of old reverse osmosis membranes used in desalination plants | UNESCO Centre for Membrane Science and Technology - UNSW Sydney

- Optimisation of hybrid coagulation/submerged membrane bioreactor treatment of wastewaters | UNESCO Centre for Membrane Science and Technology - UNSW Sydney

- Developing national validation guidelines for MBRs in water recycling

- Assisted forward osmosis for energy savings in RO desalination

- Characterising nanostructure functionality of conventional and advanced polymeric membranes using electrical impedance spectroscopy

- Optimising low-pressure membrane pre-treatment for desalination | UNESCO Centre for Membrane Science and Technology - UNSW Sydney

Process design & modelling

- Computational fluid dynamics modelling of Membrane Bioreactors

- Resilience modelling of advanced water treatment plants

- Mechanical reliability of microporous membranes in water recycling applications

- Optimisation of Membrane Distillation Processes

- Feedback Destabilizing Control of Electro-osmotic Flow

Food & agriculture

- Membrane facilitated subsurface drip irrigation

- Milk ultrafiltration

- Protein recovery from potato processing water using ultrafiltration membrane

- Phosphorus recovery from wastewater

- Sequential chemical and enzymatic cleaning of ultrafiltration membranes in dairy applications

- Application of membrane separation process in concentration and separation of polyphenol compounds for evaluation of their health benefits

- Optimising low-pressure membrane pre-treatment for desalination

Archived research projects

- Composite biocatalytic nanoflower

- Superhydrophobic Membranes for Membrane Distillation Applications

- Polymers for Isoporous and Functional Membranes

- Separation performance of dip-coated microporous hollow fibre polymer inclusion membranes (PIM)

- Improvement in Fouling Release Properties of Ultrafiltation PVDF Membranes

- Thin Film Nano-composite Membrane Fabrication for Carbon Dioxide Capture from Flue Gas

- MOF based highly efficient gas separation membrane

- Biocatalytic membrane reactors for greenhouse gas capture

- Evaluation of CO2 Capture with High Performance Hollow Fiber Membranes from Flue Gas: A Pilot Scale Study

- Improved Carbon Dioxide Separation Performance with Additives of PEO/PDMS Copolymer in PPO Membranes

- Our facilities

- Our services

- Contact us

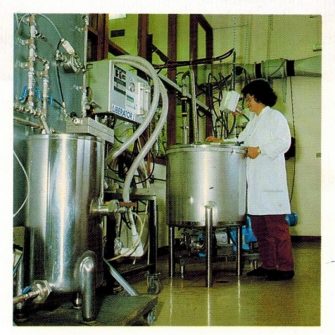

Membrane distillation-crystallization (MDC) process has great potential for recovery of high quality water and valuable precipitates from effluents of high salt content such as inland brine water. Incorporation of submerging membrane in a feed tank provides opportunity for saving of energy consumption by eliminating the need for feed circulation and reduces the loss of heat. The main challenges in submerged vacuum membrane distillation crystallization (SVMDC) are the reduction of feed temp...

Membrane distillation-crystallization (MDC) process has great potential for recovery of high quality water and valuable precipitates from effluents of high salt content such as inland brine water. Incorporation of submerging membrane in a feed tank provides opportunity for saving of energy consumption by eliminating the need for feed circulation and reduces the loss of heat. The main challenges in submerged vacuum membrane distillation crystallization (SVMDC) are the reduction of feed temperature (temperature polarization) and the enhancement of feed concentration (concentration polarization) adjacent to membrane surface, which can cause reduction of actual driving force for water vapour transport and induce fouling formation on the membrane surface. Several strategies to reduce the temperature polarization, concentration polarization and fouling are studied, such as thermal water softening as pre-treatment, transverse vibration of the membrane, aeration of feed, periodical air-backwash and periodical cleaning. Those strategies, when conducted simultaneously, results on higher water production and longer operation time of SVMDC. Even though the evaluation of the feed temperature and feed concentration adjacent to membrane surface are important for the process efficiency, it cannot be done experimentally. Numerical simulations were conducted using ANSYS-FLUENT to predict the profile of feed temperature and concentration at various feed concentration, feed temperature and vacuum pressure.

- Resarch team

- Funding body

Helen Julian

Hongyu Li

ARC Discovery DP130104048