Science

Materials Science & Engineering

- Home

- About us

- Study with us

- Our research

-

Student life & resources

-

Undergraduate program plans pre 2024

- Bachelor of Engineering (Materials Science & Engineering) (Honours)

- Bachelor of Engineering (Materials Science & Engineering) (Honours)/Master of Biomedical Engineering

- Bachelor of Engineering (Materials Science) (Honours)/Commerce

- Bachelor of Engineering (Materials Science & Engineering) (Honours)/Engineering Science

-

Undergraduate program plans 2024 onwards

- Bachelor of Engineering (Materials Science & Engineering) (Honours) New Program 2024 Onwards

- Bachelor of Engineering (Materials Science & Engineering) (Honours)/Master of Biomedical Engineering New Program 2024 Onwards

- Bachelor of Engineering (Materials Science) (Honours)/Commerce New Program 2024 Onwards

- Bachelor of Engineering (Materials Science & Engineering) (Honours)/Engineering Science New Program 2024 Onwards

- Postgraduate program plan

- Course outlines

- Important information for all coursework students

- Work integrated learning

- Careers and industries

- Student societies

- Exchange programs

- Life on Campus

-

Undergraduate program plans pre 2024

- Engage with us

- News and events

- Home

- About us

- Study with us

- Our research

-

Student life & resources

Undergraduate program plans pre 2024

- Bachelor of Engineering (Materials Science & Engineering) (Honours)

- Bachelor of Engineering (Materials Science & Engineering) (Honours)/Master of Biomedical Engineering

- Bachelor of Engineering (Materials Science) (Honours)/Commerce

- Bachelor of Engineering (Materials Science & Engineering) (Honours)/Engineering Science

Undergraduate program plans 2024 onwards

- Bachelor of Engineering (Materials Science & Engineering) (Honours) New Program 2024 Onwards

- Bachelor of Engineering (Materials Science & Engineering) (Honours)/Master of Biomedical Engineering New Program 2024 Onwards

- Bachelor of Engineering (Materials Science) (Honours)/Commerce New Program 2024 Onwards

- Bachelor of Engineering (Materials Science & Engineering) (Honours)/Engineering Science New Program 2024 Onwards

- Engage with us

- News and events

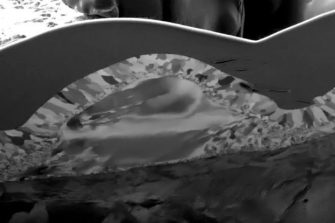

Crazing

Often, when an amorphous brittle polymer is loaded in tension, a phenomenon known as crazing can occur. Crazing involves the formation of small crack-shaped regions that are drawn down but remain constrained by the surrounding material.

The drawn material ends up as ligaments that link the crazed surfaces. Eventually the crazes form cracks that lead to fracture. The crazes contain air giving them a white streaked appearance.

Shear banding

Shear banding is produced in polymers when they are exposed to compressive stresses.

Small stress relieving cracks nucleate within the polymer parallel to the direction of maximum shear stress at an angle of 45°.

As the number of shear bands accumulates the overall strain of the material increases.