Sun-derperfoming? Why a new wave of solar panels may lose their spark too soon

The newest photovoltaic systems may promise to be the most efficient ever produced, but question marks about their longevity mean they risk proving to be a false economy.

The newest photovoltaic systems may promise to be the most efficient ever produced, but question marks about their longevity mean they risk proving to be a false economy.

Did you know that the newest solar panels on the commercial market, using the very latest cutting-edge technology, can decline in performance up to 50 per cent inside just a few years in some cases?

The photovoltaic industry has been intensely focused on increasing the efficiency of PV modules and making the electricity generated ever-more affordable.

To sustain efficiencies the industry has been transitioning from traditional PERC (Passivated Emitter and Rear Contact) solar cells to more advanced technologies called TOPCon (Tunnel Oxide Passivated Contact) and HJT (HeteroJunction Technology).

Read more: Green policies will maximise photovoltaic potential and minimise future energy costs

However, this new generation of cells introduces new reliability challenges, primarily due to their sensitivity to contaminants and light. Research by UNSW and other institutions has uncovered inherent vulnerabilities in TOPCon and HJT solar cells, especially concerning metal contacts and thin films.

Many of these potential failure modes - that is any of the different ways the photovoltaic modules can degrade in performance - are not currently detectable by standard industry testing and could drastically diminish the performance of these systems in real-world applications.

Without addressing these identified failure modes, there could be a performance decline of over 50 per cent in just a few years, negating the advantages of their initial high efficiency and resulting in a significant increase in the cost of electricity from photovoltaics.

The challenges faced by TOPCon and SHJ (Silicon Heterojunction) solar cells fall into two main categories. Firstly, the metal contacts in these cells are prone to corrosion.

TOPCon cells, in particular, have front contacts that are highly susceptible to corrosion from various contaminants, especially when water penetrates the module. Similarly, HJT solar cells, which use low-temperature metallisation paste on both sides, are also vulnerable to corrosion.

Unfortunately, once corrosion occurs, it is irreversible and cannot be remedied in the field.

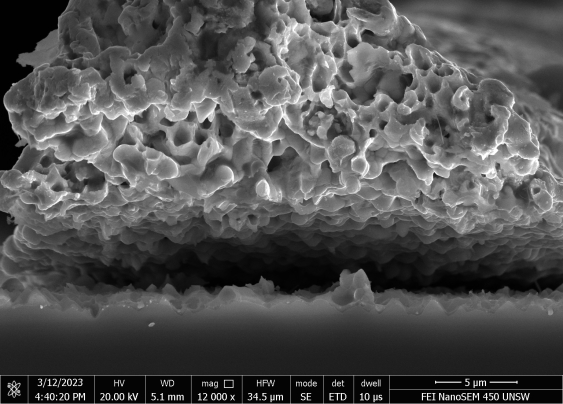

Scanning electron microscopy image of a failed metal contact at the front of a TOPCon solar cell after accelerated testing. The metal contact has detached from the silicon due to a reaction with sodium. Image from Bram Hoex

Secondly, the thin films used in both TOPCon and HJT solar cells exhibit sensitivity to light exposure. Both types are affected by ultraviolet light, and HJT cells show additional sensitivity to other parts of the solar spectrum. Interestingly, this sensitivity can sometimes enhance HJT cell performance.

However, light-induced degradation is often manageable in the field. It can be mitigated by altering operating conditions or through natural repair processes during nighttime.

UNSW and other international research groups are intensively studying the underlying mechanisms of these new failure modes in solar cells. By comprehending the fundamental causes, we aim to devise effective solutions at both the cell and module levels.

A key challenge is that these failure modes may develop over decades in the field, and waiting that long to address them is not feasible.

To overcome this, there is a focus on creating rapid testing methods that accelerate these failure modes. Such methods allow for faster evaluation of mitigation strategies and the development of new product generations.

At UNSW, we have developed several advanced testing methods for solar cells. These methods provide insights up to a hundred times faster than traditional accelerated testing used in the photovoltaic industry.

These tests are not only faster but are also tailored based on a deep understanding of the specific failure modes. This approach has already led to the development of effective solutions to combat corrosion-related degradation in both TOPCon and HJT solar cells.

A UNSW researcher measuring the current-voltage characteristics of an industrial TOPCon silicon solar cell. Image from Bram Hoex

The photovoltaic industry must tackle these reliability concerns at the cell or module level, and the leading suppliers have mainly opted to address these issues effectively at the module level using better but more expensive materials. It's particularly important for end-users, especially large-scale operators, to engage their suppliers with critical inquiries.

They should question how these suppliers have addressed the identified reliability issues and what specific tests have been performed to confirm the effectiveness of these solutions. This proactive approach will ensure that the photovoltaic systems they acquire are both efficient and durable.

Improved reliability in photovoltaic technology will lead to lower electricity costs for society as well as maintain society’s trust in renewable energy technologies. This enhancement is crucial for both mitigating human-induced climate change and bolstering energy security.

As photovoltaic systems become more dependable, they contribute significantly to sustainable and economically viable energy solutions.

Renewable energy is key in addressing human-induced climate change. The economic and environmental impacts of these energy sources depend heavily on their anticipated or actual lifespan.

For photovoltaics, the vast majority of costs and environmental impacts are incurred during the production of the photovoltaic system.

Therefore, it is imperative that these systems operate efficiently for as long as possible.

* Professor Bram Hoex, from the UNSW School of Photovoltaic and Renewable Energy Engineering, is an expert in solar cell/module reliability.