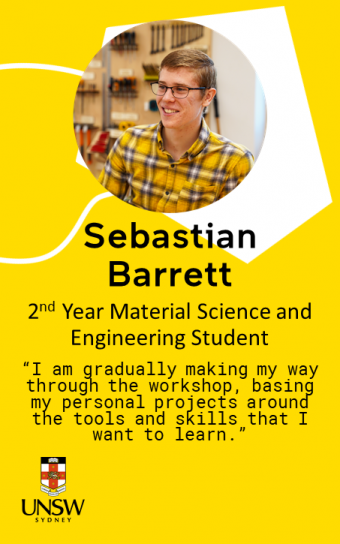

I have made it my goal to learn how to use the UNSW Makerspace’s specialised equipment to turn my designs into a reality. I wondered what beautiful art or random projects I could create with access to amazing tools, machines, and expertise from the makerspace technical officers. I am gradually making my way through the Makerspace workshop, basing my personal projects around the tools and skills that I want to learn.

When I wanted to learn how to laser cut, I decided to make a clock as most of the parts can be cut from sheet acrylic. I asked a lot of questions, tested, asked more questions, designed, went to Bunnings, and asked yet more questions! The friendly makerspace staff answered my constant stream of questions, although they thought that they would never end (and they haven’t). Eventually, I was able to work out my design and manufacture it from scrupulously saved acrylic scraps. I learnt lots about laser cutting, computer aided design and made some great friends along the way.

My next target was the CNC mill (Computer Numerical Control), which can cut wood and metal to produce computer designed parts. Things would often go wrong during the manufacturing process, and I found myself in suspense, nervously waiting to see if anything would break. After learning the basics, my big project was to make a puzzle box; an eight-piece cube fitted together by a variety of funky joints I designed. After lots of tolerance testing and rethinking, I was able to watch six weeks of design be milled into reality. Just to make the cube look extra cool I lasered parametric swirls into the sides.

Recently, I have learnt how to 3D print, which has opened endless opportunities for time wasting, designing cool spirally and spiky figures. By combining the manufacturing skills from these three machines, I have made a board game with awesome geometric pieces and laser cut tiles and coins.

I received a lot of help from all the staff in the makerspace and wish to thank them for answering my questions and always being happy to teach me.